What is Trimble RTX in GNSS?

Trimble’s Real Time eXtended (RTX) correction service is a global GNSS correction source used to attain precise GNSS positioning. It operates the same as using a local base station, or Virtual Reference Station (VRS), to reduce the errors in GNSS positioning. Without corrections, a GNSS rover is only accurate to about 16 feet +/-. With corrections, GNSS rover positions are accurate to 0.02 to 0.06 feet.

How Does RTX Work?

RTX does not require the additional hardware typically associated with GNSS positioning, such as a local base station and radio communications. Currently, broadcast corrections are received by the existing L-Band antenna in our rovers and no additional communication equipment is required. All that is required is a subscription to RTX and an SPS 985, SPS 986, or an R750 receiver.

What is RTX Used For?

You can use RTX in any phase of your project where the accuracy requirement is around 0.06’ horizontal and 0.16’ vertical.

Typical RTX Applications

- Pre-bid existing surface verification

- Site volume calculations

- Offsite utility locations

- Offsite barrow pit volume calculations

- Finding existing control

Using RTX for these types of applications reduces setup time, as no base station is required.

As an example, let’s look at an offsite barrow pit application.

First Measurement of the Pile

- Set two rebars or nails in the ground.

- Setup and configure the local base station on one of the points.

- Connect our rover to the base via the radio.

- Perform a single point calibration to the other point.

- Save the base location as a control point.

- Then we can start measuring the pile.

Return Visits to Determine the Volume of Material Moved

To be able to calculate the volume of material moved, we need to be on the same coordinate system as the first time. We would also need to have the same project in our data collector as it contains the calibration information.

- Setup and configure the local base station on the same point (if it’s still there) as the first visit.

- Connect our rover to the base via the radio.

- Check the other control point to make sure we are on the same coordinates.

- Then we can measure the pile and calculate the volume of material moved.

First Measurement Using RTX

- Configure the rover for RTX corrections and select the State Plane zone we are in.

- Measure the pile.

Return Visits Using RTX

Since we are using the RTX and a State Plane zone, no additional steps or data is required.

- Configure the rover for RTX corrections and select the State Plane zone we are in.

- Measure the pile.

- Calculate the volumes.

Benefits from the Example Barrow Pit Exercise

- Setup time is greatly reduced

- No base station required. This frees up the base to work at the project site.

- No control points or site calibration required; all positions are in a published coordinate system.

- Barrow Pit can be located anywhere, does not need to be near the site

- No radio communications required

How does it work?

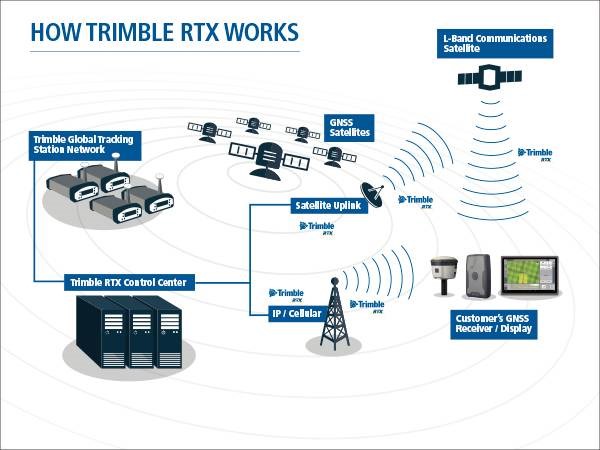

To achieve accurate GNSS positions, a correction source is required. GNSS positioning accuracy is affected by atmospheric conditions and orbital errors. A correction source computes the data required to reduce/eliminate these errors, providing accurate GNSS positioning.

To achieve accurate GNSS positions, a correction source is required. GNSS positioning accuracy is affected by atmospheric conditions and orbital errors. A correction source computes the data required to reduce/eliminate these errors, providing accurate GNSS positioning.

Trimble’s RTX corrections are computed using a global tracking station network of more than 100 stations. The number and distribution of these stations can accurately model the atmospheric conditions for the entire coverage area. This eliminates the distance restrictions typically used with a local base station.

In most use cases, the corrections are transmitted and received on a L-Band signal, eliminating the need for additional communication equipment. Corrections are also available over the Internet which requires an Internet connection at the rover.

Does Trimble RTX check all the boxes to improve your workflow efficiencies and add time to your schedule? Get a FREE 3-day demo to get a first-hand experience of real-time, sub-inch accuracy today!