Tracking Operations Has Never Been Easier

Construction payload weighing systems by Trimble® and Caterpillar® monitor a range of equipment data during material loading and transfer. Depending on the product, these systems provide real-time access to payload weight and distribution while collecting and storing data to improve operational efficiency, profitability and performance.

At SITECH Southwest, we distribute the full line of Cat Payload and Trimble LOADRITE™ solutions for optimizing weight and utilizing your fleet to its maximum potential. From scales to in-cab monitoring systems, these construction payload weighing systems can be used for many applications on remote job sites and permanent installations.

Trimble LOADRITE Payload Management for Trimble Earthworks Grade Control Platform

Maximize your machine control investment with integrated payload management. Track how much weight is in each bucket and how much weight has been added to a cycle.

Maximize your machine control investment with integrated payload management. Track how much weight is in each bucket and how much weight has been added to a cycle.

LEARN MORE

Trimble LOADRITE Excavator Scales

Half-full or half-empty, if your haul trucks aren’t carrying their optimized load you’re probably wasting money. With the X2350 on your excavator, you’ll know exactly how much material is loaded in the truck, and you’ll minimize costs and cycles to haul it away.

Half-full or half-empty, if your haul trucks aren’t carrying their optimized load you’re probably wasting money. With the X2350 on your excavator, you’ll know exactly how much material is loaded in the truck, and you’ll minimize costs and cycles to haul it away.

LEARN MORE

Trimble LOADRITE L3180 Wheel Loader SmartScale

Accuracy and precise loading that adjusts for rough terrain, technique, and movement so new and skilled operators can load with greater accuracy, precision and speed.

Accuracy and precise loading that adjusts for rough terrain, technique, and movement so new and skilled operators can load with greater accuracy, precision and speed.

LEARN MORE

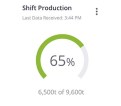

Trimble Insight Dashboard

Productivity and efficiency visualization in one, easy-to-use dashboard.

Productivity and efficiency visualization in one, easy-to-use dashboard.

LEARN MORE

LOADRITE H2250 Haul Truck Monitor

Real-time haul truck production and process monitoring, driving increased production and limiting costs.

Real-time haul truck production and process monitoring, driving increased production and limiting costs.

LEARN MORE

InsightHQ: Operations Reporting Portal

InsightHQ is an operations management portal to show real-time productivity, availability and performance dashboards and reports.

InsightHQ is an operations management portal to show real-time productivity, availability and performance dashboards and reports.

LEARN MORE

Smart Haul: Load and Haul Tracking

Automated dig-to-dump material tracking.

Automated dig-to-dump material tracking.

LEARN MORE

LOADRITE C2880 Belt Scales for Fixed Plant

Track production and efficiency for every product, and the entire plant.

Track production and efficiency for every product, and the entire plant.

LEARN MORE

LOADRITE C2850 Mobile Machine Belt Scales

Increase the profitability of your operations and monitor quarry performance, productivity and stockpile inventory with Trimble LOADRITE mobile conveyor belt scales.

Increase the profitability of your operations and monitor quarry performance, productivity and stockpile inventory with Trimble LOADRITE mobile conveyor belt scales.

LEARN MORE

LOADRITE 360 Loadout Management System

LR360 connects the loader and scale house for job data sharing which result in greater efficiency, improved visibility and higher product sales.

LR360 connects the loader and scale house for job data sharing which result in greater efficiency, improved visibility and higher product sales.

LEARN MORE

LOADRITE L2150 Loader Scale

A high precision onboard loader scale for accurate and reliable weighing with basic data functions.

A high precision onboard loader scale for accurate and reliable weighing with basic data functions.

LEARN MORE

LOADRITE Force Loader Scales

Quickly and easily load trucks exactly to their target weight with a simple interface.

Quickly and easily load trucks exactly to their target weight with a simple interface.

LEARN MORE

LOADRITE L2180 Loader Scales

The World's Most Popular Wheel Loader Scale

The World's Most Popular Wheel Loader Scale

LEARN MORE

Contact Us

Our Locations

SITECH Southwest continues to proudly hold its position as the premier technology solutions provider for the Construction, Mining, Agriculture, Landfill, and Quarry & Aggregates industries. With unwavering commitment, we offer our exceptional services to Nevada, Arizona, and Southeast California, solidifying our reputation as the trusted leader in these regions.

Contact us at one of our convenient locations below to get started.